Cole Roskam, University of Hong Kong

Summary

Bricks were essential if obdurate components in the physical and figural construction of the People’s Republic of China (PRC)—a building material rooted in China’s civilizational origins yet new and vital to the country’s built environment under Mao. It was a familiar object for some but not all of China’s residents, and it required a certain but not necessarily highly skilled expertise to produce and assemble into architecture. In both its enduring and multivalent practicality and representational agency, the brick is a useful object through which the aspirations and challenges of realizing an everyday socialist modernity in the PRC may be better understood.Introduction

What makes the brick an important object to study in relation to socialist Chinese history? In short, the brick reminds us of the inherent difficulties in rapid, transformative change while drawing our attention to the fact that change can, and often does take place through existing technologies that are not necessarily new but rooted in the technics of use. As the astrophysicist Fang Lizhi 方励之 (1936 – 2012) wrote in his memoir detailing his punishing ordeal making bricks during the Cultural Revolution, 'they were asking us to use a two-thousand-year-old method of firing bricks to fire up China’s modernization.'1 Early party slogans promising residents 'two-story houses, electric light, and telephones' (loushang louxia, diandeng dianhua 楼上楼下电灯电话) reminded citizens that revolution would deliver new technologies, environments, and construction practices.2 Here, the brick was an important ideological component to the development of socialist China. Yet the brick’s value also lay in the fact that it also carried real weight as an established building material capable of transitioning China from one physical reality into another.

The Brick in early Mao-era China

Over the course of the early 1950s, new brickmaking methods, material innovations, and other related technologies proved vital to the realization of a new China. A building manual titled Making Bricks and Tiles (Zuo zhuan-wa 座砖瓦), published by Xu Yunzhong of Shanghai Zhonghua College just five months after the establishment of the PRC, argued for the rapid dissemination of a technique like quality brick and tile production to average people, along with access to the necessary skills, technologies, and physical facilities.3 In the face of China’s immediate economic obstacles, however, Xu also reasoned that a revival of old earthen brickmaking techniques and brick kilns presented an advantageous interim strategy that would empower the country’s brick makers and reactivate kilns in psychologically productive ways.4

Ideologically, however, this proved sensitive; a new China required new architecture. Over time, the brick was transformed into a socialist object through the introduction of new production and bricklaying methods. Early model workers like Su Changyou 苏长有 (1925-1981), for example, were nationally promoted for their innovative and efficient new bricklaying techniques. In this respect, brick proved valuable both as an agent capable of giving physical form to a new China and facilitating the daunting transitional processes required to realize it. [See ⧉source: Su Changyou’s advanced bricklaying techniques]

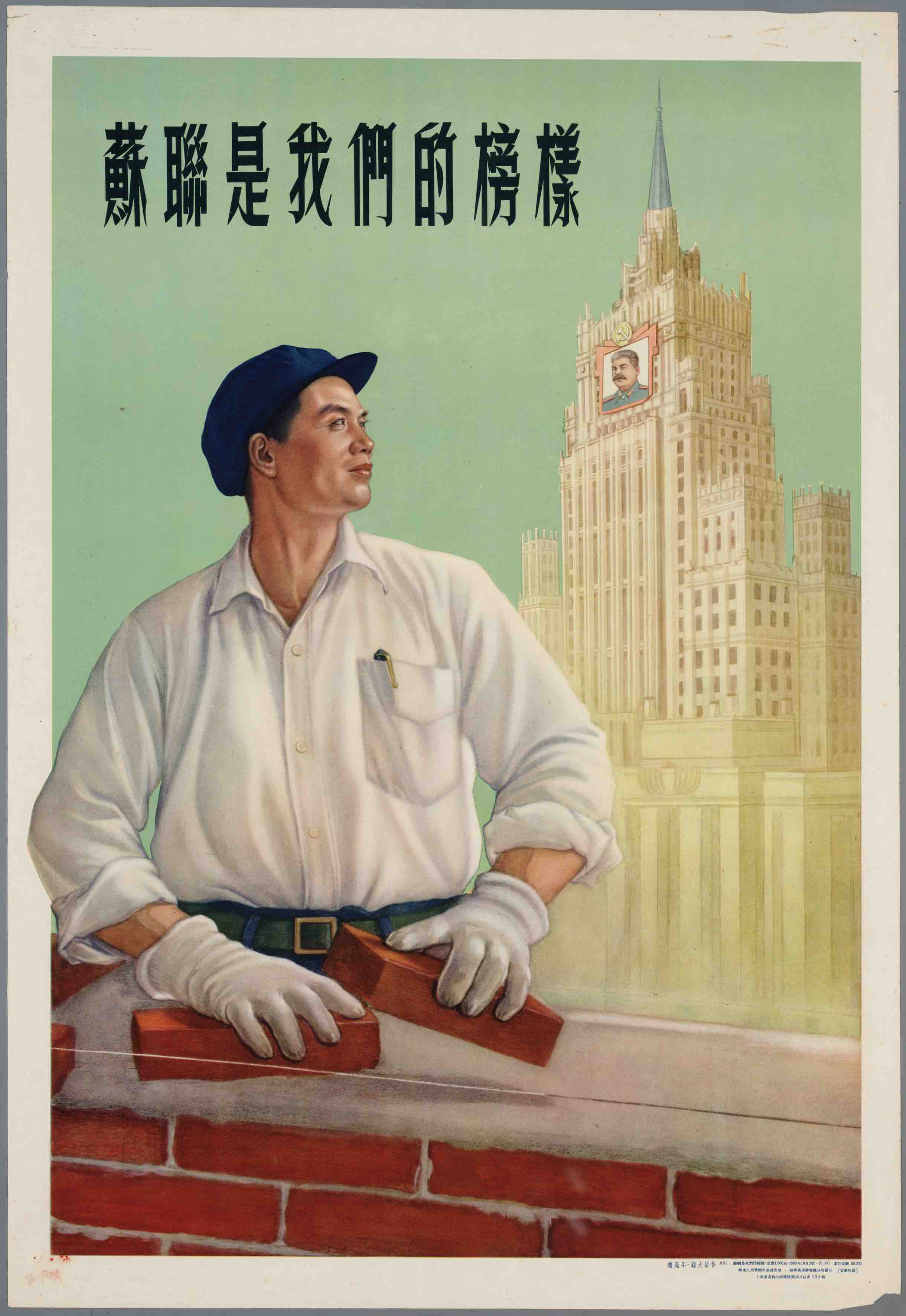

Many of these new practices were also imported into the PRC from the Soviet Union, which played a formative role in the PRC’s early architectural and engineering history. A 1959 building manual titled Ceramic Hollow Bricks (Taozhi kongxinzhuan 陶质空心砖), originally published in Cyrillic by A.C. Dmitriev in 1956, offers lessons in brick and block production based upon experiences in Moscow and Ukraine intended for application in China.5 Yet China was itself so lacking in basic building expertise that such documents also served as uncomfortable reminders of how far China had yet to advance to be considered on par with its Soviet mentor or the socialist world more generally–a fact tacitly captured by the three-year lag between the original document’s publication and its translation into Chinese. [See ⧉source: 'The Soviet Union is our model' poster, also depicted to the left; see ⧉source: Illustrated manual of brick construction practices]

From the Great Leap Forward to the Cultural Revolution

The launching of the Great Leap Forward in 1958 was designed in part to address the technological gap between China and both the socialist and capitalist worlds. Although it is the backyard steel furnace that remains perhaps the most emblematic symbol of collectivized service to the state during the Great Leap Forward, makeshift brick kilns were also important contributors to China’s modernization. Built primarily in urban areas around the country, kilns allowed residents to excavate mud and transform it into bricks, which could then be used for housing or to reinforce underground shelters. In Beijing, where mud kilns appeared next to giant piles of earth, there was a quota of thirty bricks per person.6 In Shanghai, one report enthused, 'people took the initiative to tear down their own chicken sheds and fish tanks, and some even took the bricks used to prop up their beds and furniture, reinforce their walls, elevate their stoves or pave their floors. People also donated coal to operate the improvised kilns, which apparently produced 7 million bricks—not counting those salvaged or scavenged from existing structures.' 7

A December 1959 scrapbook detailing brick chimney production techniques, performance data, and design details from Liaoning offers further insight into the brick’s complex agency in China’s physical development. The manual was assembled by a state-owned but locally administered architectural and engineering company based in Liaoning, and it begins with a foreword introducing the company’s efforts to implement local steel smelting facilities in 1958. In an effort to channel air pollution produced by the facility away from the community, the company decided to construct a chimney capable of pushing the smoke out and above the village. Reinforced concrete was proposed and initially implemented during the construction phase, but the group found deficiencies both in the material’s quality and in their ability to produce it, and they eventually switched to brick chimney construction. The company acknowledged that although brick construction was a long-established building technique in the Soviet Union, it was still new for most of China. As a result, they had to come to terms with China’s situation and fumble about looking for a suitable solution. The implementation of such technology, they lamented, was both 'complicated and simple' (fanjian 繁简).8 Despite these limitations, however, the company was inspired by the bold, inspiring call for action under the Great Leap Forward to build a sixty meter-tall brick chimney. They muddled through the process, documenting and collating their experimentation in text and drawings into a manual for other interested building companies. [See ⧉source: On materiality]

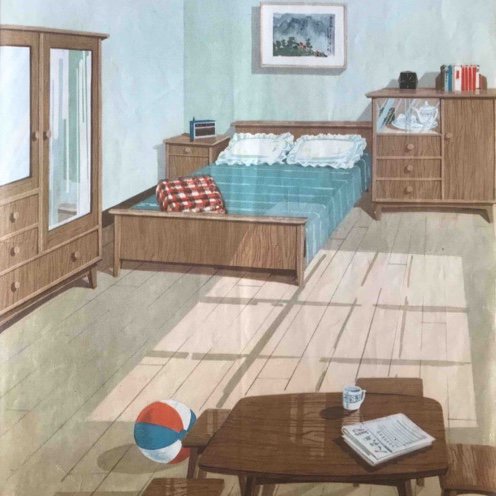

By the late 1950s, Chinese engineers were being exposed to a range of brick technologies previously adopted and mastered by the Soviet Union. These methods included fly ash brick production, which offered a means of recycling burned coal waste into a reusable building material, and hollow brick and block construction, which provided a lighter, more economical product than what had previously existed in China. These techniques were generally restricted to China’s cities, where there existed adequate infrastructure and technical expertise to support them. By contrast, standardized brick production and construction methods were much more difficult and expensive to implement in rural China; as Jacob Eyferth’s study of the lives of rural women in Guanzhong reminds readers, standardized, kiln-fired bricks and tiles were rare if not altogether non-existent throughout China’s countryside before the 1970s.9 A Mao-era history of the brick is thus primarily a history of urban China, and it was there that much built evidence of a socialist Chinese modernity, imagined and realized through brick production, emerged. By 1961, the publication Architectural Journal (Jianzhu Xuebao 建筑学报), the country’s most widely circulated architectural design magazine, was disseminating idealized renderings of multistory dormitory residences for factory and mining employees in places like Kunming, Yunnan, Xinjiang Autonomous Region, and Hebei Province [See ⧉source: Architectural Journal]

The Brick through Revolution and Reform

The brick’s worth as a measurable index of labor and a physical technology also allowed it to weather ideological fluctuations in Mao-era rhetoric. By the mid-1960s, communes, government offices, and institutions around the country could boast of their own brick production facilities, ensuring that residents and workers were responsible for the physical construction of their own living and working environments. During the Cultural Revolution, these facilities were transformed from sites of pride to objects for punishment. In Hefei, Anhui Province, for example, the astrophysicist Fang Lizhi worked alongside colleagues in mathematics, physics, mechanics, medicine, and chemistry at the University of Science and Technology in China (Zhongguo Kexue Jishu Daxue 中国科学技术大学) producing bricks for campus construction projects.

By 1972, China’s built environment had begun to register the effects of these distinctive, on-site methods of cooperation through the appearance of numerous smaller-scale brick production facilities and more modest, locally constructed architectural objects around the country. Prefabrication remained in use during the Cultural Revolution, but changes to the process of assembly affected the quality of China’s construction practices and constructed objects. Architects no longer 'supervised' construction, but rather were there to 'help the workers.'10 These constraints encapsulated the broader difficulties of realizing Mao’s vision for China’s modernization through decentralized collectivity—challenges the brick’s deceptively humble ontology helped to mask. Brick production could still be relied upon as a tangible index of progress, though it also, on occasion, inadvertently exposed the era’s violent dysfunction. In 1971, for example, Shanghai tried to establish a new record in brick production in run-up to National Day by building a number of new brick kilns around the city. One of these devices in the Putuo district imploded, burying or injuring twelve people. Kilns posed a hazard until the mid-1970s.11

By late 1972 and 1973, shifts in brick production constituted part of China’s gradual economic and political project toward liberalization, which aimed at re-centering the party and its rhetoric around a more technocratic, as opposed to ideological, identity. These changes renewed the brick’s value both in theory and in practice—an object still capable of conditioning the country for rapid and unpredictable physical and political transformation. Beginning in 1974, the party began to promote a construction movement known as the 'hollow block and wall reform' (kongxin qikuai ji qiangti gaige 空心砌块及墙体改革), which encouraged the introduction and dissemination of several variations of prefabricated brick and cement building block production throughout the country in the name of improving socialist Chinese building practices. Like the political, economic, and cultural engagement with capitalist countries supported by Zhou Enlai and others at the time, the hollow brick and wall reform movement represented a subtle shift away from the themes of fervent class struggle emphasized by Cultural Revolution-era rhetoric and practice. Hollow brick and block production existed in the 1950s and 1960s but had not been comprehensively implemented around the country. The reemergence of these technologies augured political and economic transformations within the state itself, and the first, tentative gestures toward more dramatic economic liberalization to follow. [See⧉source: Wall reform booklet, also depicted to the right]

Ultimately, a biography of the brick during the Mao era offers a history of limits. One might presume the mundane specificities of brick’s modular anonymity, coupled with its long, largely unheralded history in China, would have restricted its semiotic possibilities in Mao-era China. Masonry construction itself is constrained by its own load capacity, the presumed simplicity of its production, and by its own rather everyday quality, leaving it seemingly lacking the conceptual force of an object like the steel I-beam, with its evocations of industrial progress, formal and spatial innovation, and structural potential. Nevertheless, the brick endures as a key component of China’s material culture, and a fundamental building block in the study of post-1949 China’s architectural history. This is in large part due to the brick’s capacity to induce seemingly attainable expressions of popular aspiration through process, space, and form.

Footnotes

Fang Lizhi, The Most Wanted Man in China: My Journey from Scientist to Enemy of the State (New York: Henry Holt and Company, 2016), 153.

Jacob Eyferth, 'Liberation from the Loom? Rural Women, Textile Work, and Revolution in North China', in Maoism at the Grassroots: Everyday Life in China’s Era of High Socialism, edited by Jeremy Brown and Matthew D. Johnson (Cambridge, MA: Harvard University Press, 2015), 131.

Xu Yunzhong 徐蕴中, Brick and Tile Making (Zuo Zhuanwa 做砖瓦) (Shanghai: Zhonghua shuju gufen youxian gongsi, 1950), 3.

Zu, Zuo Zhuanwa, 4.

A.C. Dmitriev 德米特里耶夫, Hollow Earthenware Bricks (Taozhi kongxin zhuan 陶质空心砖), trans. Long Jian. Originally published in Moscow, 1956 (Beijing: Jianzhu gongcheng chubanshe yinshuachang yinshua, 1959).

Frank Dikötter, The Cultural Revolution: A People’s History (London: Bloomsbury, 2016), 213.

Dikötter, Cultural Revolution, 213; PRO, 'Underground construction in Peking,' August 25, 1970, FCO 21-683; Shanghai, August 29, 1970, B120-2-7, 1-11; March 3, 1973, B120-2-26, 45-46.

'Foreword’, Brick Chimney Design Materials (Zhuan yancong sheji ziliao 砖烟囱设计资料) (unpublished building manual).

Jacob Eyferth, 'Liberation from the Loom?', 152.

Walter Wagner, 'A Report… on Life and Architecture in China', Architectural Record (September 1974): 116.

Dikötter, Cultural Revolution, 213.

Sources

- ⧉ IMAGE

- 文 TEXT

- ▸ VIDEO

- ♪ AUDIO

Geography

Plans for new brick residential housing on Jiefang Road in Wuhan, Hubei Province were published in Architectural Journal in June 1961 as evidence of unprecedented levels of productivity taking place in the city. Plans and elevations of four distinct, five-story models, each designed to accommodate standardized two-, three-, and four-bedroom units and additional amenities such as light wells and balconies, provide a glimpse of the new socialist reality taking shape through material innovations like more efficient brick production.

Five new residential units designed for construction on the campus of Shanxi University, Taiyuan, Shanxi Province, were published in Architectural Journal in June 1961. Collectively, the units were capable of supporting teaching staff equivalent to 171 households, with each person allocated approximately 6-7 square meters of space. Standardized layouts helped to reduce design and building costs while gesturing toward the broader promises of socialist modernity offered by new technologies like standardized brick and block production.

Timeline

Further Reading

Campbell, James W.P. Brick: A World History. London: Thames and Hudson, 2003.

Edgerton, David. The Shock of the Old: Technology and Global History since 1900. Oxford: Oxford University Press, 2007.

Legault, Réjean. 'Louis Kahn and the Life of Materials.' In Louis Kahn: The Power of Architecture. Weil am Rhein: Vitra Design Museum, 2013: 219-233.

Li Qinglin. 'Zhongguo gudai zhuanwa shengchan zhong "Jiaoshui zhuanyou" jishu de qiyuan yu fazhan'. Kaogu yu wenwu no. 1 (2016): 96-104.

Lloyd, Nathaniel. A History of English Brickwork. Orig. published 1925. New York: Benjamin Blom, Inc., 1972.

Schwenkel, Christina. 'Post/Socialist Affect: Ruination and Reconstruction of the Nation in Urban Vietnam.' Cultural Anthropology vol. 28, no. 2 (2013): 252-277.

Taylor, Frederick Winslow. Scientific Management. Originally published 1911; New York: Harper & Row, 1964.

Vidler, Anthony. 'Another Brick in the Wall'. October 136 (Spring 2011): 105-132.